US Hospital Market Overview

(American Hospital Association. ‘20)

- 6093 Hospitals/920, 531 beds

- Annual Spend of $1.1T

- Target grouping sm fewer 100 Mid 100-499, Large 499+

- Gartner report sighted that 37.% of total cost of patient care was attributed to supply chain spend

- Supply Chain Management Systems (SCM) can reduce cost

- 60% reduction in backorders

- 30% reduction in logistics and handling

- 20% reduction through better pricing

- 95% of 39 US health providers said they wanted an increase to planning and more than half don’t have a plan for it

Current SCM Solutions

- Barcode Scanners (Wavemark, Tecsys, BlueBin, Oracle)

- Nurses pull materials using scanner

- System updates use, ordering and provides visibility

- Additional time required by staff

- Weight Based System (Identi)

- Overly sophisticated

- Hard to manage and recalibrate

- Traditional KANBAN two bin systems

- ALL REQUIRE ADDITIONAL LABOR or DO NOT Remove Labor

As noted previously, hospitals see value in analytics as noted by Gartner, Deloitte and other studies going back years.

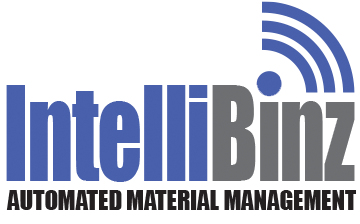

Current Hospital Supply Chain

Annual Spend

- SM Pa’s IRMC

- 10 storage rooms/$57M spend with 200 bins/room

- Med UC Health

- 400 storage rooms/$50M spend with 125 bin average/room

- Large Northwestern University Hospitals

- 1000+ storage rooms/$1B spend with 100+ per storage room, 100,000+ bins, several additional clinics as well managed by high cost nursing staff

Some rooms very small. Little correlation between bins/room and spend per hospital/size as of yet

All have a manual front end

All see the value in analytics

All understand the value of insight for best practices and negotiation

Cost of Daily Counting

- UC Health estimated at $2100 daily/$63000/month*

● NWH estimated at over $5000/day or $150k per month*- Nurses cost more

- Loaded labor/FTE $28/hr for non clinical staffCounting is done by physically observing empty

- bins then using a handheld scanner to order refill

- Information confidence is low/empty only INFO

- Analytics based on use only

- Hospitals still forced to use dated two bin KANBAN system

- Substantial nursing issues with hoarding and lost time and patient care due to running out of product

- Substantial two digit waste for lost or expired products 12-18% (25% clinical staff have used or witnessed using expired products with patient)

* figures confirmed by hospital supply chain leadership

How do the economics work?

Prevalent Hospital Issues Post Covid

Labor shortage/Increased labor cost

Supply chain accuracy identified as a way to cut costs and improve efficiency

backlog/waste/inefficient use

One Deloitte study found 24% of clinical staff witnessed the use of expired or outdated supplies

Of 400k surveyed nurses, physicians, service line leaders and supply chain admin, 2/3rds said they have experienced data related challenges (quality, availability and integration issues)

What is the financial story?

Cost reduction 37% of patient care are supplies; SCMs can:

60% reduction in backorders

30% reduction in handling costs

20% reduction in improved pricing

Double digit waste reduction (for a mid sized hospital this can be millions)

50% LABOR reduction with Intellibinz

Eliminate upfront counting FTEs

More accurate data

Ability to proactively set alerts

Reduction in supply hoarding

Reduction in supply department theft

Improved staff morale and workload

Mid sized hospital saves $60+K/month in labor alone

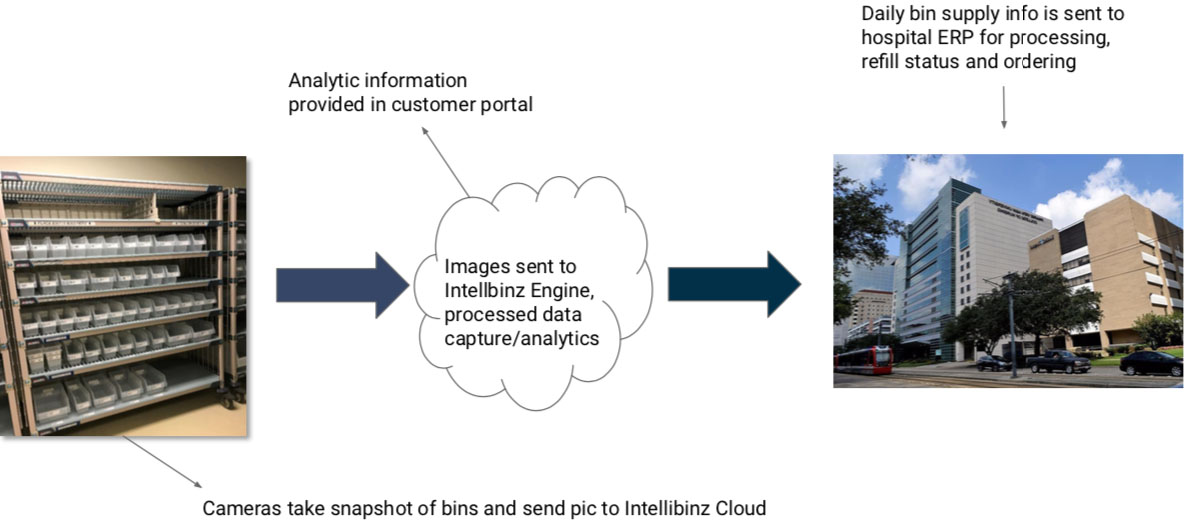

How the Intellibinz solution works

Intellbinz Camera System

Custom install of Intellibinz camera strip above bins in storage racks

Pics taken, routed to Intellibinz Cloud

- Daily, hourly pic options

Intellibinz Engine

- Pics checked via database determining status

full/empty, phase 2 thresholds, phase 3 counts

Value returned via engine updating database for order status by product/room/location

Info sent to customer updating their order requirements, removing upfront labor $$

Intellibinz updates database for analytics/insight solution

Insight

- Intellibinz database analysis for predictive insight across organization

- Info provides hospital groups the ability to negotiate more favorable contracts (Deloitte study 20% cost reduction)

- Predictive analytics will help storage room thresholds preventing waste and inefficiencies

- Waste reduction reduced by double digits through SCMs

- Comparable analysis for best practices preventing backorders

- Improved budgeting across supply chain/across organization

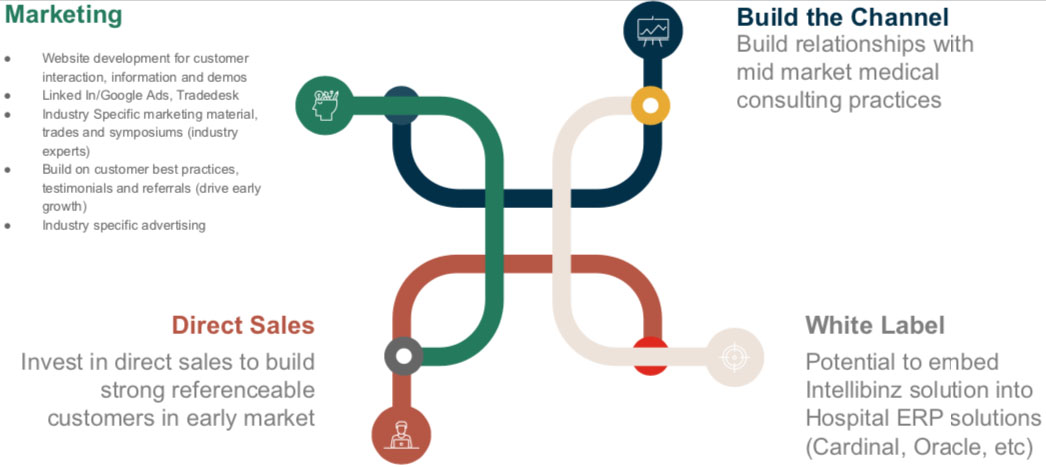

Go To Market Strategy