Intellibinz: an Automated Supply Chain Solution

- Addresses hospital labor issues

- Provides information across material use

- Provides accurate data for increased efficiency

and reduced waste - Improves staff morale and patient care

- Integrates with existing ERP platforms

- Saves money

- Provide visibility across enterprise

- Core architecture utilizes latest machine learning and customized predictive analytics (AI)

Cost of Counting

- Must physically observe empty bins and scan for a refill

- Analytics based on low/empty bin count only

- Information confidence is low/empty only INFO

- Forced to use dated KANBAN system

- Issues in nursing: hoarding, lost time, and reduced patient care due to low inventory

- 12-18% of inventory is lost or expired and thrown away

- 25% of clinical staff have used or seen others use expired products

- Often only empty bins are accounted for

Analytics and Insight

- Provides hospital with ability to negotiate favorable contracts (Deloitte, 2022)

- Helps storage room thresholds, preventing waste and inefficiency through SCMs

- Analysis of trends allows for best practices, preventing backorders

- Improves budgeting

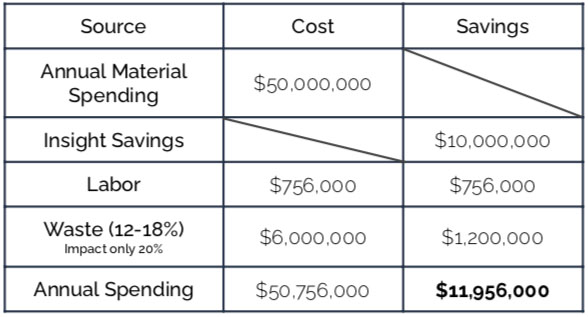

Sample ROI for Midsized Target Hospital

Current Spending

- $50M annually

- 48,000 bins

- Cost inefficiencies, 20% savings

- $6-9M in annual waste, lost or theft

- $63,000 monthly/$756,000 annual front end counting cost

- What if we only achieve half of the industry savings projections

- What would you do with a complete view of the supply chain instead of just empty bins across the enterprise